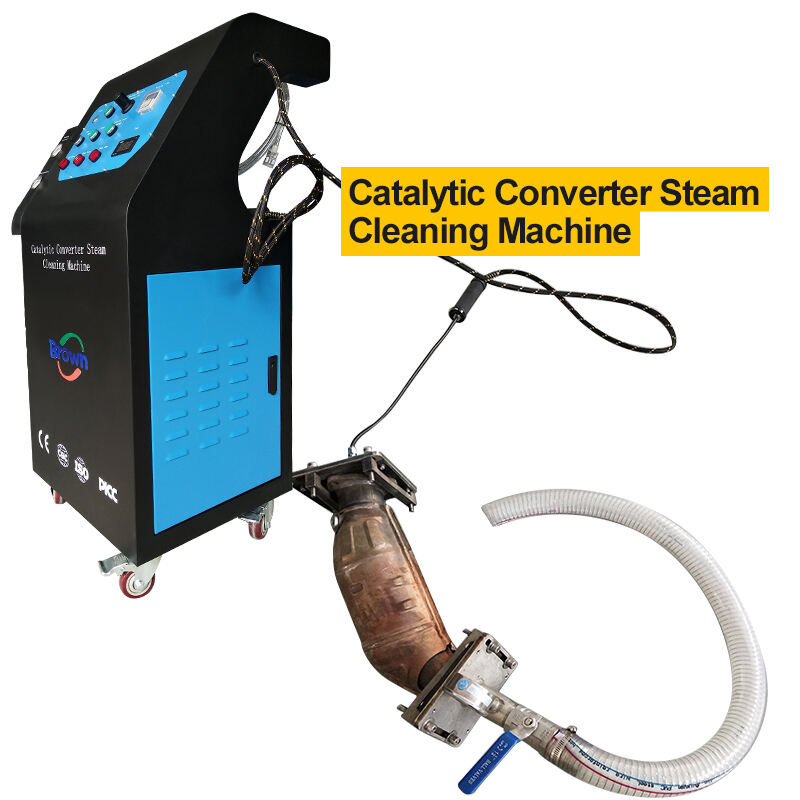

High Efficiency Emission System Restoration Catalyst Cleaning Machine

We are a pioneer high-technology manufacturer with a focus on integration of R&D, consulting, and business operations. We design and manufacture specialized machines which clean catalytic converters by removing carbon, oil, and other contaminants. Our machines incorporate state-of-the-art technology such as steam cleaning systems, autonomous parameter control, and green cleaning. Supported by a professional engineer team, complete production lines along with ISO and CE certifications, our solutions restore catalysts to optimal function while lowering emission and extending equipment life, admired globally for their dependability and performance.

Get A Quote