Pneumatic DPF cleaning machine

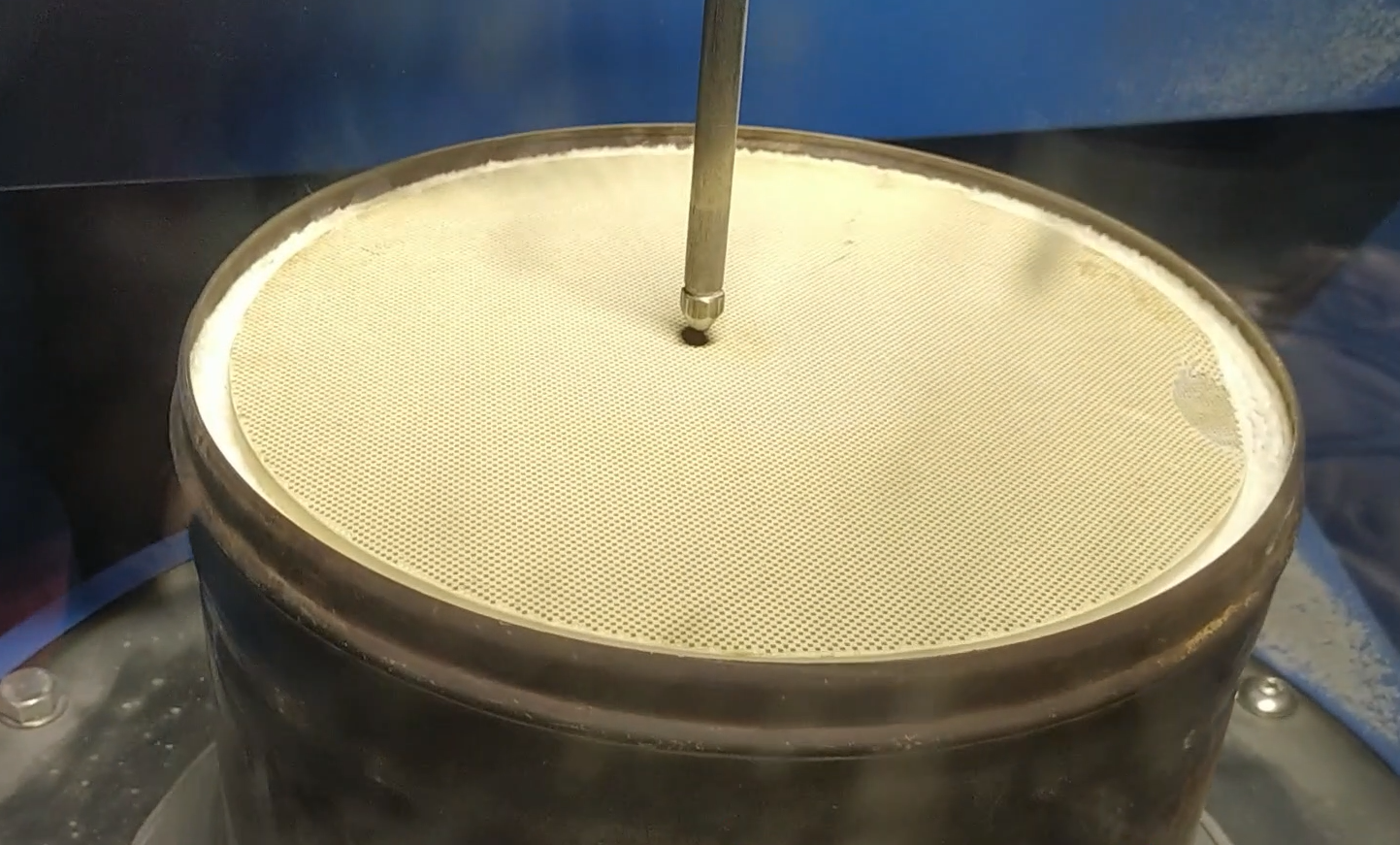

By using unique bi-directional scanning technology to blow off soot&ash particulates from each cell of DPF, then dust collector sucks all released dirties, ensures efficiently DPF cleaning and regeneration.

- Overview

- Recommended Products

Product Parameters

Model Number |

BR-IPC-MA01 |

Dimensions |

1450mm*750mm*2040mm |

Net Weight |

450kg |

Input power |

220V |

Rated power |

3kW |

Air scanning pressure |

0.3-0.7Mpa |

Filtration system |

Two-stage filtration: cyclone dust collector and HEPA filter two-stage filtration |

By setting up a high-temperature regeneration furnace to heat the DPF carrier at 600℃, carbon particles are degraded. After natural cooling, the DPF carrier is blown clean by an air knife. Finally, the dust cleaning effect is detected by a back pressure detection system, which is energy-saving, environmentally friendly, has a short regeneration time, and meets the National VI emission standard

Principle of DPF pneumatic blowing and cleaning machine

Perform double-sided automatic blowing and cleaning on the DPF, blowing the ash and carbon particles in the DPF away from the DPF carrier, and attaching them to the outer surface of the filter through negative pressure suction and air duct. Finally, by blowing back high-pressure air, the attached ash is blown away and settled in the ash receiving bucket for subsequent treatment, achieving the purpose of DPF regeneration.

Characteristics of DPF Pneumatic Blowing and Cleaning Machine

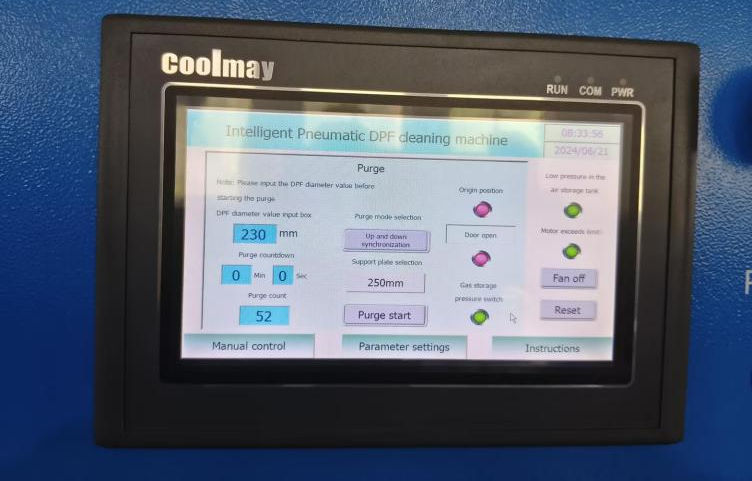

● Comprehensive coverage: The turntable and blowing nozzle scan type blowing ensures that every hole in the DPF is fully covered with blowing, leaving no blind spots.

Dual directional blowing: Simultaneously perform automatic blowing and cleaning on both ends of the DPF. (Can also be set as one-way blowing)

● Scheduled blowing: The cleaning time can be set.

● Full visibility: The cleaning process can be observed in real-time through a transparent window.

● Cleaning range: DPF of various sizes (diameter 140mm~430mm, height not exceeding 610mm) can be cleaned.

● Two stage filtration: The air is filtered through the main filter and HEPA filter before being discharged into the atmosphere, which is environmentally friendly and pollution-free.