Converter Catalytic Steam Cleaning Machine

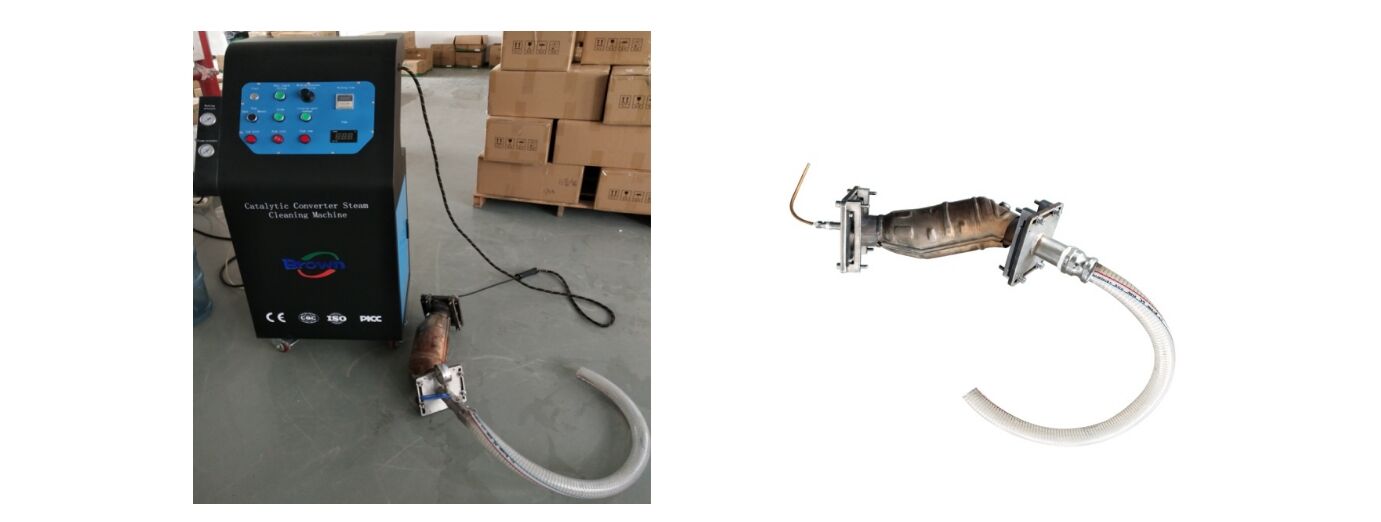

This machine is suitable for cleaning all kinds of three way catalytic converter of gasoline vehicles, and small DPF/SCR of diesel vehicles. Unique steam pressure bursting function

- Overview

- Recommended Products

Product Parameters

Model number |

BR-TGT-B03 |

Dimensions(L*W*H) |

580*655*1170mm |

Weight |

90Kgs |

Voltage |

220V |

Rated power |

6kw |

Steam pressure |

0.4-0.5Mpa |

Steam temperature |

140-150℃ |

Liquid filling tank |

15L |

Cleaning agent tank |

1L |

Steam pipe length |

3M |

Air supply |

0.3-0.4Mpa |

Application

This machine is suitable for cleaning all kinds of three way catalytic converter of gasoline vehicles, and small DPF/SCR of diesel vehicles.

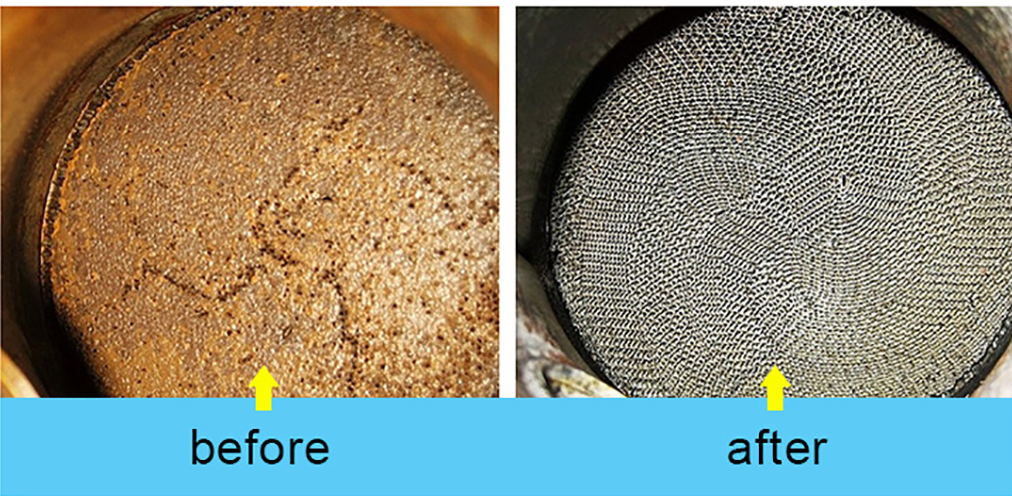

The catalytic converter is the most essential components of vehicle emission control system.Due to modern stop-and-go traffic conditions, imposed speed limits lead to insufficient combustion of gasoline and gradual accumulation of carbon deposit,particulates,complex compound etc. Therefore, vehicle will have problems of excessive exhaust emission, lack of performance, high fuel consumption, also may lead to catalytic converter lose effectiveness.

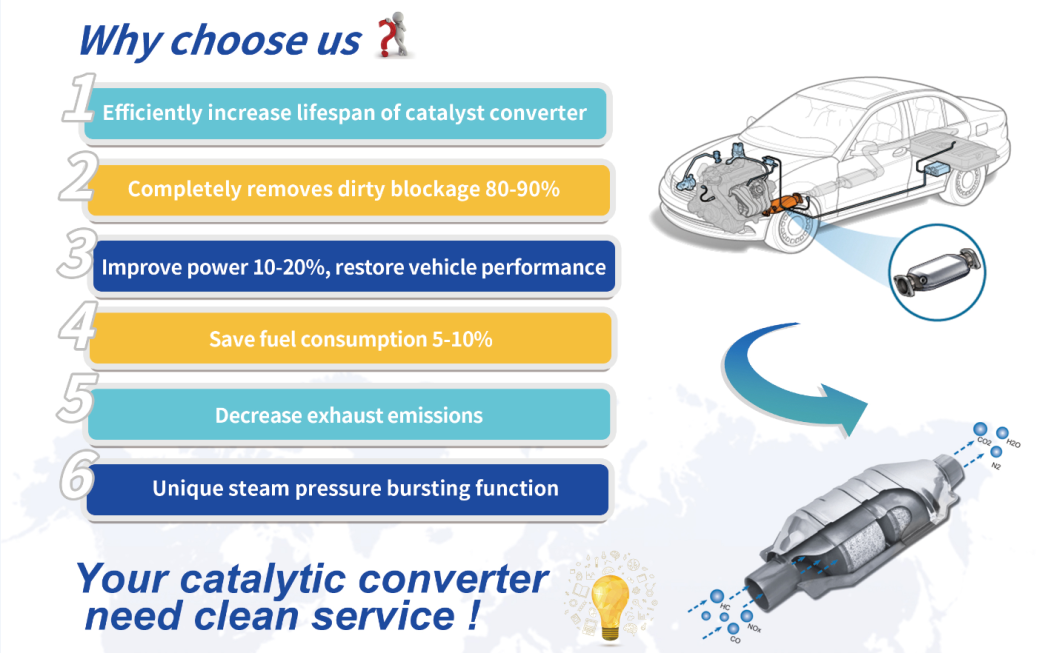

Advantages

1.High temperature high pressure steam sustained steady output, completely removes dirty blockage 80-90%.

2.By using special designed fixture+eco-friendly cleaning agent, soaking and steaming for catalyst/DPF, efficiently soften the internal carbon deposits&complex compound.

3.Unique steam pressure bursting function,even seriously blockage also can be dredged.

4.Decrease exhaust emissions (NOX decrease 25-40%,CO decrease 50-75%, HC decrease 25-40%)

5.Save fuel consumption 5-10%.

6.Improve power 10-20%, restore vehicle performance.

7.Efficiently increase lifespan of catalyst converter/DPF.

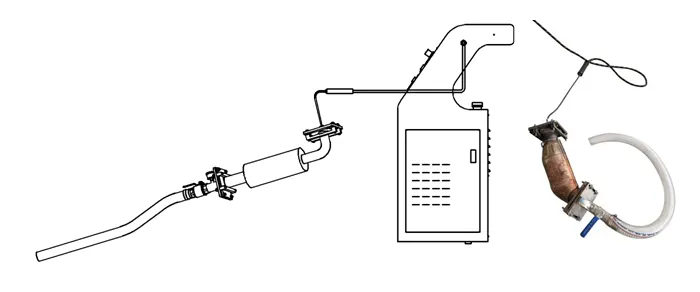

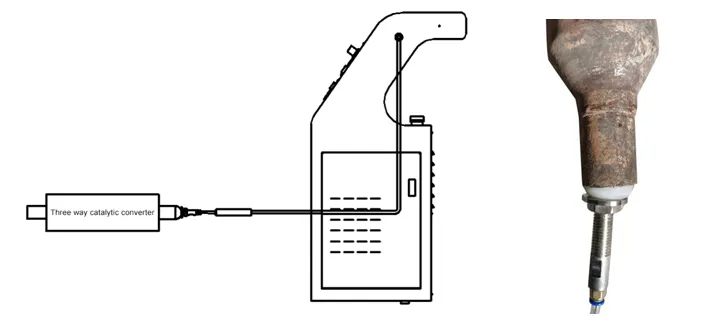

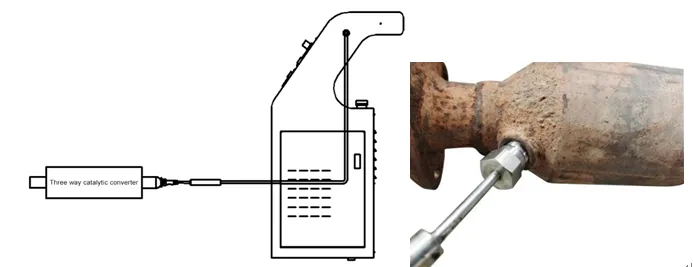

Exclusive Patent Connection method

Silicone ball connection method:The connection method of the three-way catalytic converter with a diameter of φ35-60. After installing as shown in the figure, lock the silicone ball and tighten the nut to make the silicone ball expand and squeeze the inner wall of the catalytic converter, thereby blocking one end of the catalyst for cleaning.

Nozzle connection method:Suitable for connection methods that are inconvenient to disassemble the three-way catalytic converter, Install direct nozzle or curved nozzle through the oxygen sensor mounting hole on the three-way catalytic converter for cleaning.

Fixture connection method,Suitable for flange-type three-way catalytic converter connection, with good sealing effect and high cleaning pressure.