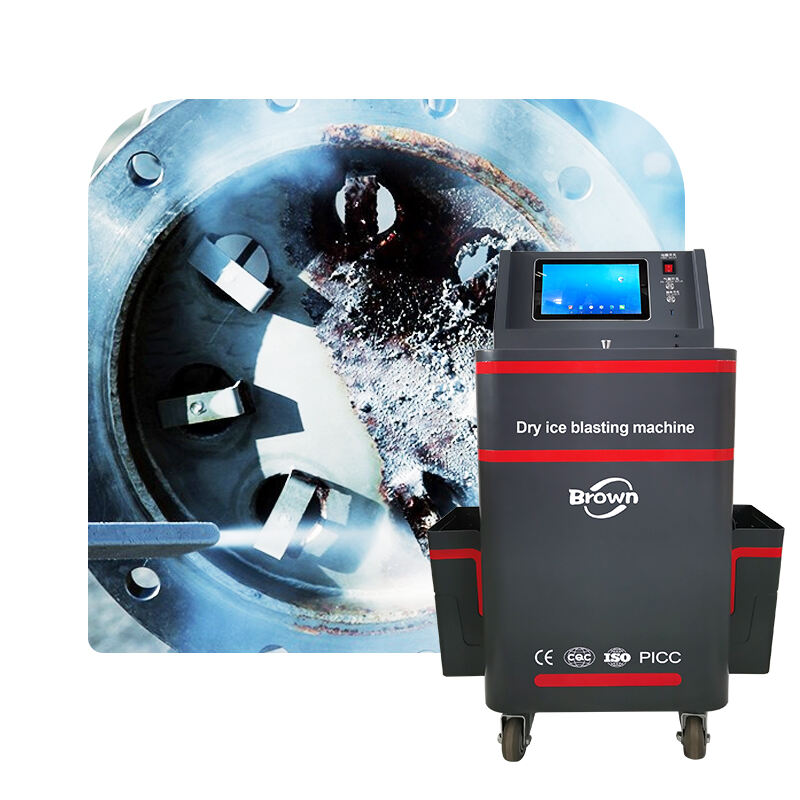

The technology we employ for automated cleaning and blasting with dry ice uses a unique method that combines application of dry ice pellets with high-pressure air streams of 120PSI for destroying stubborn deposits on parts of industrial machines, automobile engines, or even on huge structures. Systems of this type are automated and consume 20 percent less energy as compared to older systems which work non-stop and do not need a rest period. In addition, these add-on systems for vertical steel rigid protective walls of shipyard and factory buildings are unparalleled from the point of view of durability. These systems have high accuracy dry-cleaning and blasting with superb quality and precision with very low unproductive time.