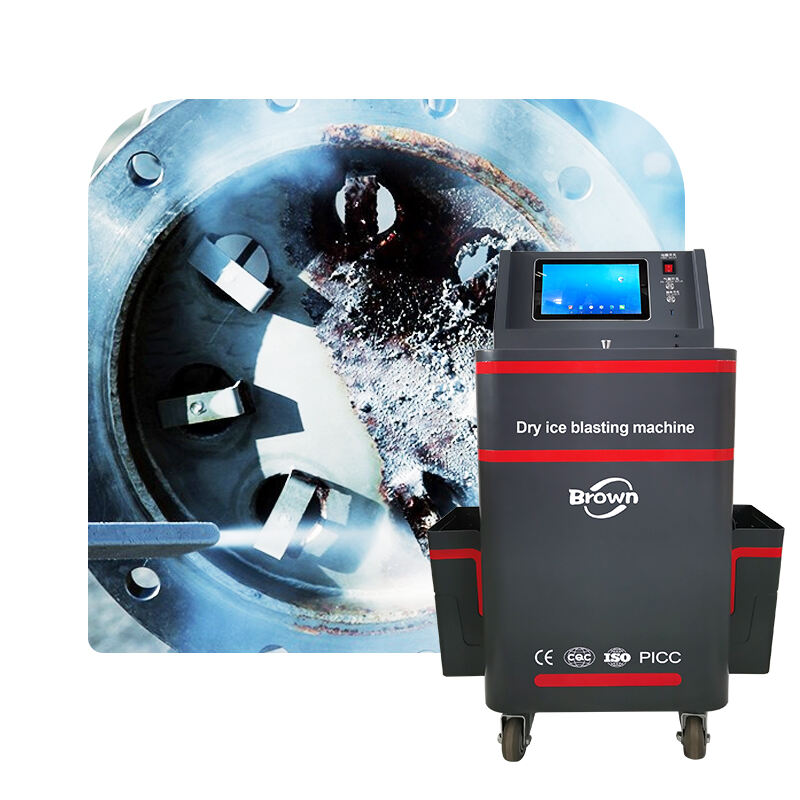

Fast Cleaning for Better Productivity

Sublimation cleaning methods that use dry ice pellets enables our customers to achieve set cleaning goals faster, being able to attend to other work related tasks. This is enhanced even more due to proper nozzles which can range from 0.3mm to 2.0mm leading to ease in switching between measuring cleaning tasks. This saves time, eliminates the need for traditional brushes and heavy machinery, steam as well as solvents. Roughly, the torso of an automobile engine bay can be restored to factory cleanliness within 30 minutes, being 50% faster than the traditional method which used solvents. For automotive mechanics and repair services, this allows the business to take on an estimated 4-6 more jobs a day.