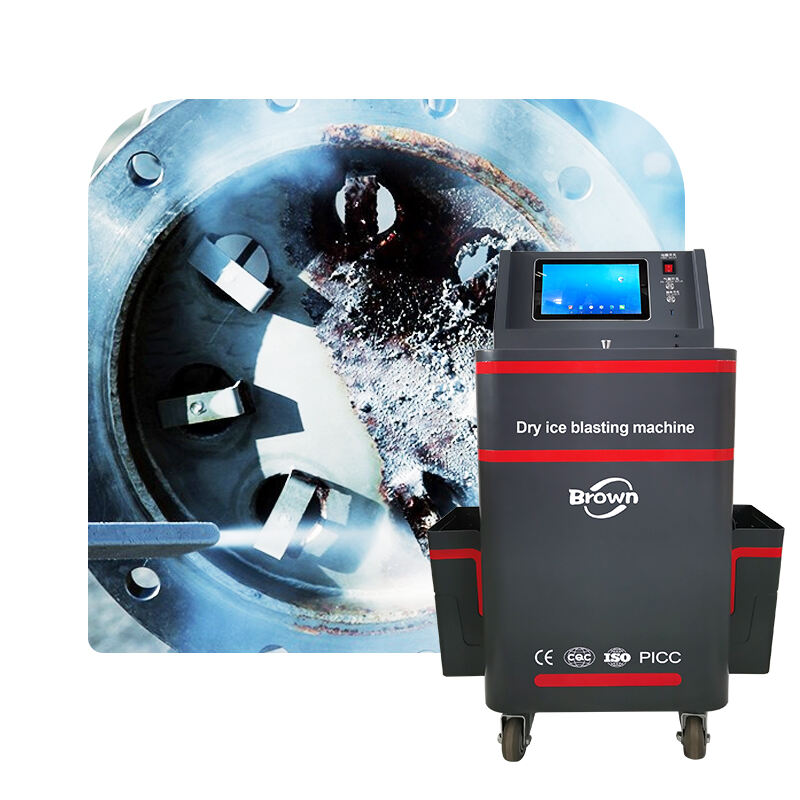

In our dry ice blasting equipment, we use dry ice sublimation to achieve an absolute reduction of 100% in the use of water and chemicals, while fully eradicating residues including dirt and contaminants. This eco-friendly method of cleaning is safe for all materials and is best suited for engine blocks, conveyor belts, as well as other industrial and electronic components. For this purpose, the machines are fitted with state of the art intuitive control systems, continuous operation high capacity pellet hoppers, quick change nozzles, etc. Consequently, we are able to utilize these in automotive and industrial workshops and manufacturing plants to greatly reduce environmental pollution and during the same time enhance productivity.