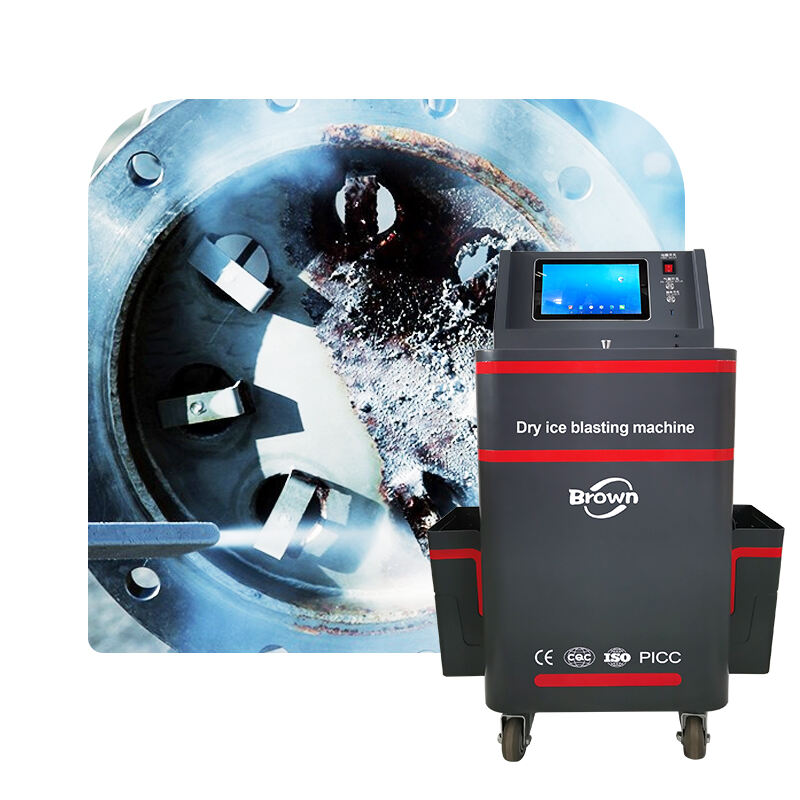

Highly precise industrial cleaners using dry ice blasting machine technology.

We are proud to be the first in the world to manufacture and sell machines offering non-abrasive and eco-friendly cleaning with dry ice, as the dry ice blasting machines enable cleaning of the engines, industrial surfaces, and molds. Our machines use pulverized dry ice pellets propelled at high speed which removes contaminants while leaving no damage or remnants. Our machines serve a variety of industries including automotive, electronics, and food processing due to the lower energy consumption […] adjustable pressure design and CE certification, certified over 9 years of exports and widespread acclaim from customers spanning the globe.

Get A Quote