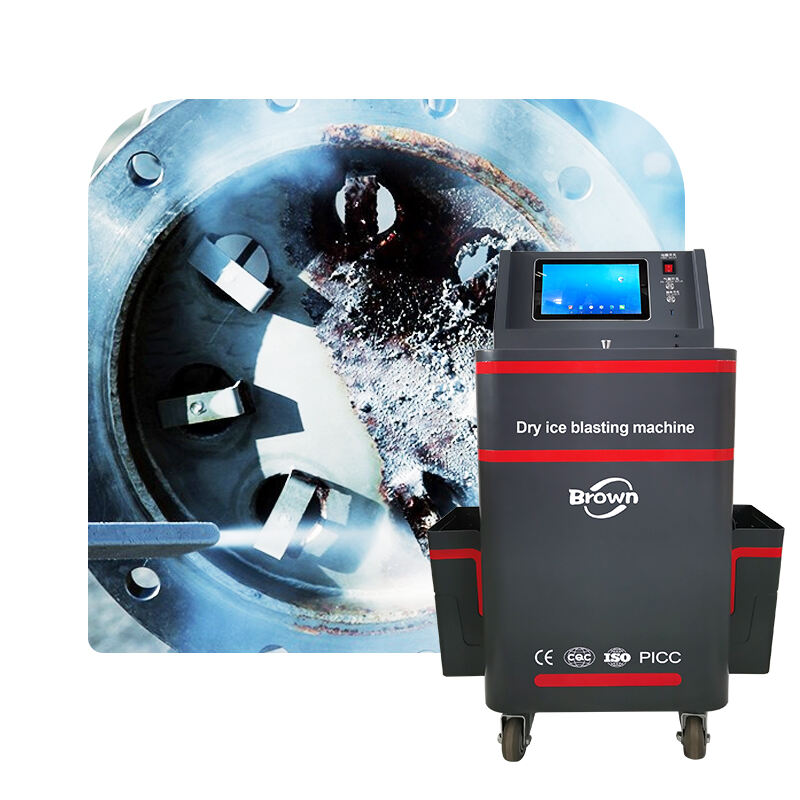

Flexible Uses Across Sectors

Our machines serve the food processing, automotive, industrial, and electronics industries which enables scalability. For automotive repair, the machines easily clean interior surfaces, engine blocks, and exhaust systems without damaging intricate coatings. Food processing plants utilize them to sanitize production lines without any chemical residues, while manufacturers of electronics use them for the static-free cleaning of sensitive PCBs. The portable units (45kg) are ideal for on-site fleet maintenance, while the fixed industrial units enable 24/7 production line cleansing with minimal downtime across all sectors.